- Stock: 15

- Model: P3Steel-frame

Available Options

Free shipping to mainland Spain, cheap to other destinations.

Pay in three interest-free installments with PayPal. 0% APR.

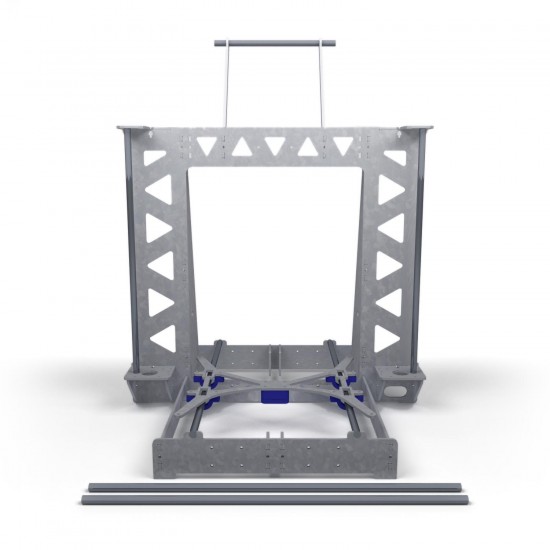

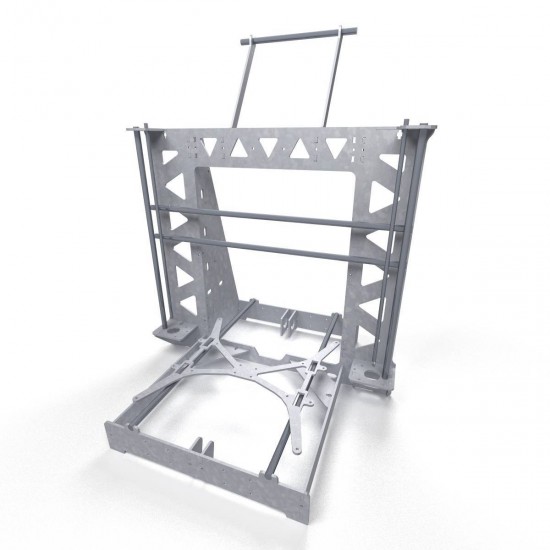

1. GALVANIZED STEEL FRAME (3MM):

Laser cutting of a high-quality galvanized steel sheet, according to our redesign, with the following improvements:

-

Dramatically lightened the Y axis carriage, in order to improve dynamic behavior.

-

Filament support included.

-

Fixed the problem with the upper left side (the extruder clashed with it), and also the problem of the nut that clashed with Y axis motor.

-

Modified the distance between the two pieces that make the Y axis tensioner, so as to hold the F624zz bearings with washers. Also, modified the hole diameter.

-

Y axis now measure 350mm, the extra 9mm are added on the front side.

-

Y axis bearing holder and Y axis belt holder are replaced by printed parts, as the metalic parts caused troubles.

2. THEADED AND SMOOTH ROD KIT (CONFIGURABLE):

-

2x 375mm Smooth Rods – Stainless Steel

-

2x 350mm Smooth Rods – Stainless Steel

-

2x 320mm Smooth Rods – Stainless Steel

-

2x 300mm M5 Threaded Rods – Stainless Steel

-

1x Smooth Rod for filament support

The cutting is done by hand, so that the meassure can be slightly higher (+ 1mm or similar) not lower. All rods are shipped without burr and the edges filed down properly.

3. EXTRA:

-

Printed parts for Y carriage:

-

Y Belt holder

-

4x Lm8uu holders

-

100% Customers recommend this product

-

5 Awesome90.63%

-

4 Great9.38%

-

3 Average0%

-

2 Bad0%

-

1 Poor0%

Reviews Over P3Steel / Prusa I3 Steel Frame - Galvanized / Stainless

- (5)

Total Reviews (32)

click here write review to add review for this product.

Report this review.

Files:

Frame:

-

DWG - v1.02 - Parts for the Y-axis motor have been modified, now the belt can be removed more easily.

Printed Parts:

-

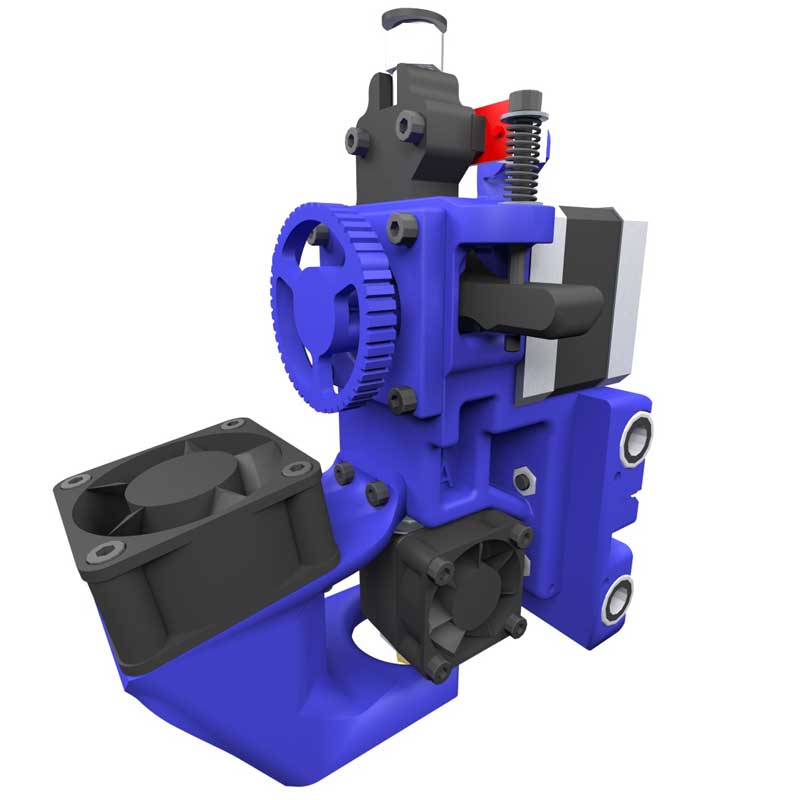

STL – v1.01 - Single extruder Version

-

STL – v1.02 - Single extruder Version - Compatible leadscrew pieces have been added and small tolerance corrections have been done

Firmware:

-

Marlin 1.1.0 RC2 - Filament presence sensor disabled - loaded by default

-

Marlin 1.1.0 RC2 - Filament presence sensor enabled

Assembly Tutorial

New step by step tutorials:

We have prepared a new updated tutorial serie, with further information about available options. Also printable, so you don't need a display to follow the instructions:

Assembly Tutorial (Spanish with english subtitles):

Important: We recommend reading the instructions in this tab completely, in addition to following the assembly from here since we have included additional information to the videos.

Updates:

- Thermistors have now dupont connector, no soldering required.

- Stepper motors include cable connector on base. In addition, we ship them with the wires in the correct order for Ramps 1.4. So you do not have to change the order.

- Marlin updated to 1.1.0 RC 7 version:

- Improved filament change system from the LCD or using command M600

- Bed leveling function optimized, get easily a perfect first layer.

- Small bugs fixed, now more information is displayed on the LCD.

Frequently asked questions:

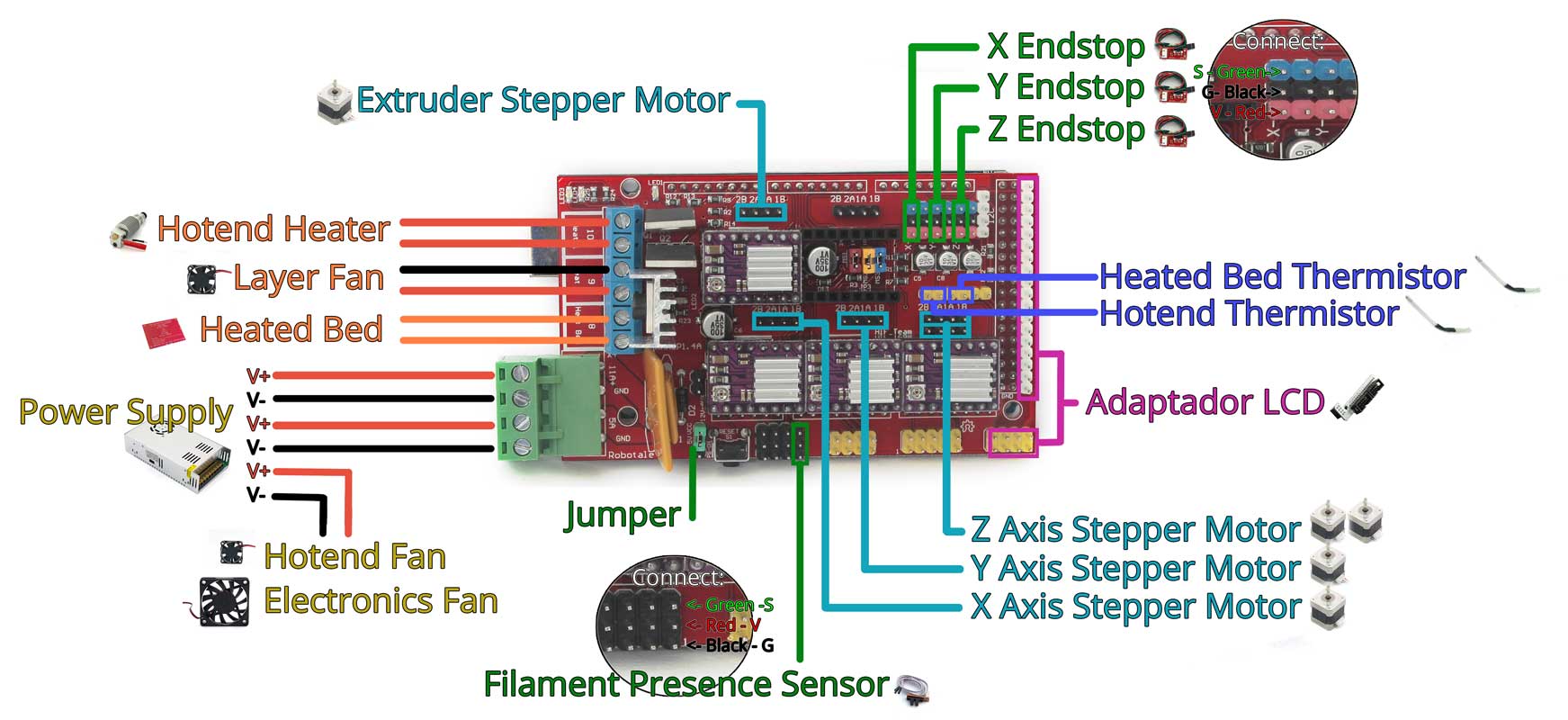

- How all fans are connected to the printer?

Fans are connected as follows:- Layer fan: Connected to D9 as indicated in the video

- Hotend fan: connected directly to 12v, the connection can be done like on the video or connected to the output of 12v on Ramps 1.4

- Electronics Fan: connected directly to 12v, the connection can be done like on the video or connected to the output of 12v on Ramps 1.4

- The extruder motor does not move when I try to move it from the LCD.

Marlin has a protection to prevent accidental movement, so the extruder will not move with temperatures under 170°C. Try heating the hotend over this temperature and the extruder will move

Assembly drawings:

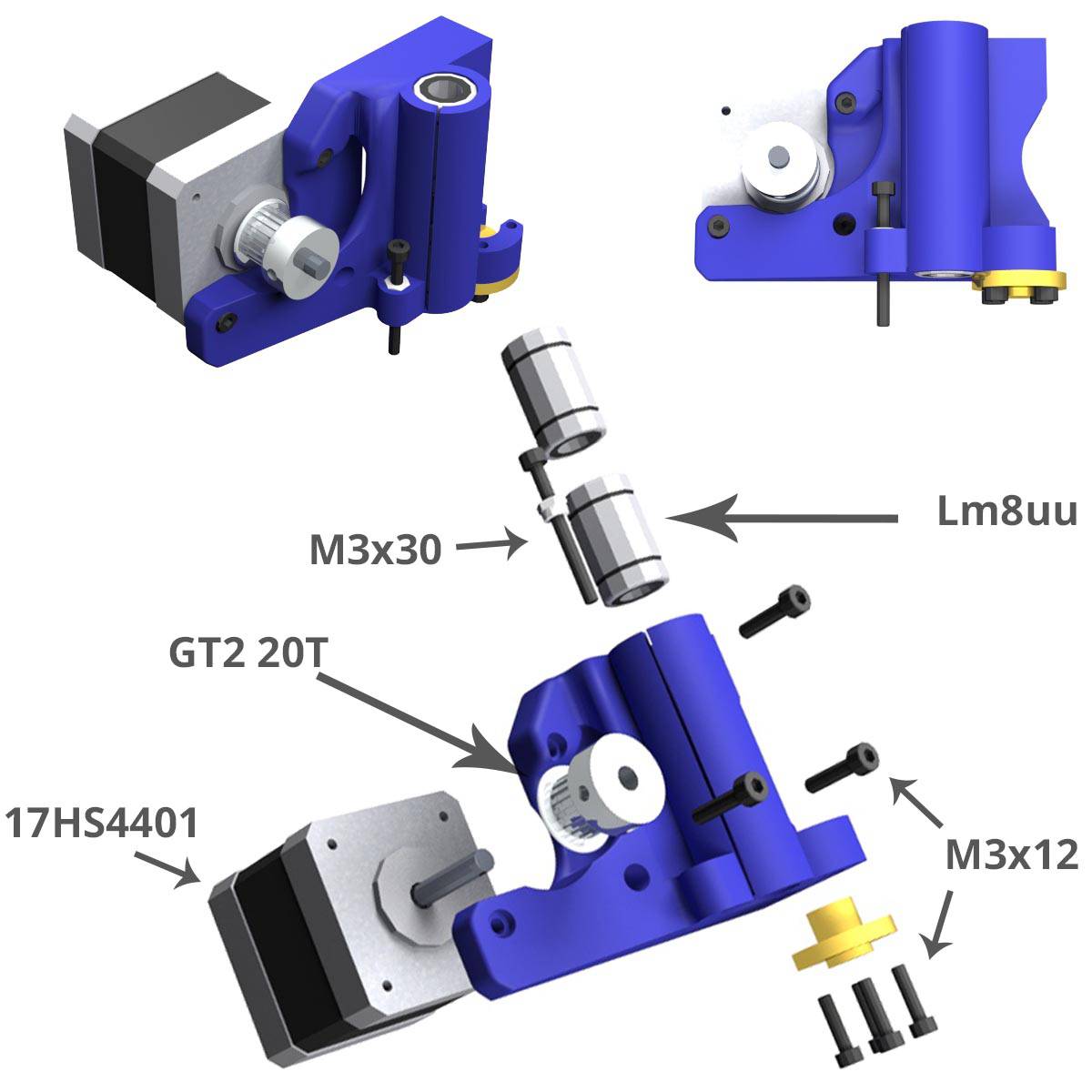

Xmotor, Leadscrews version:

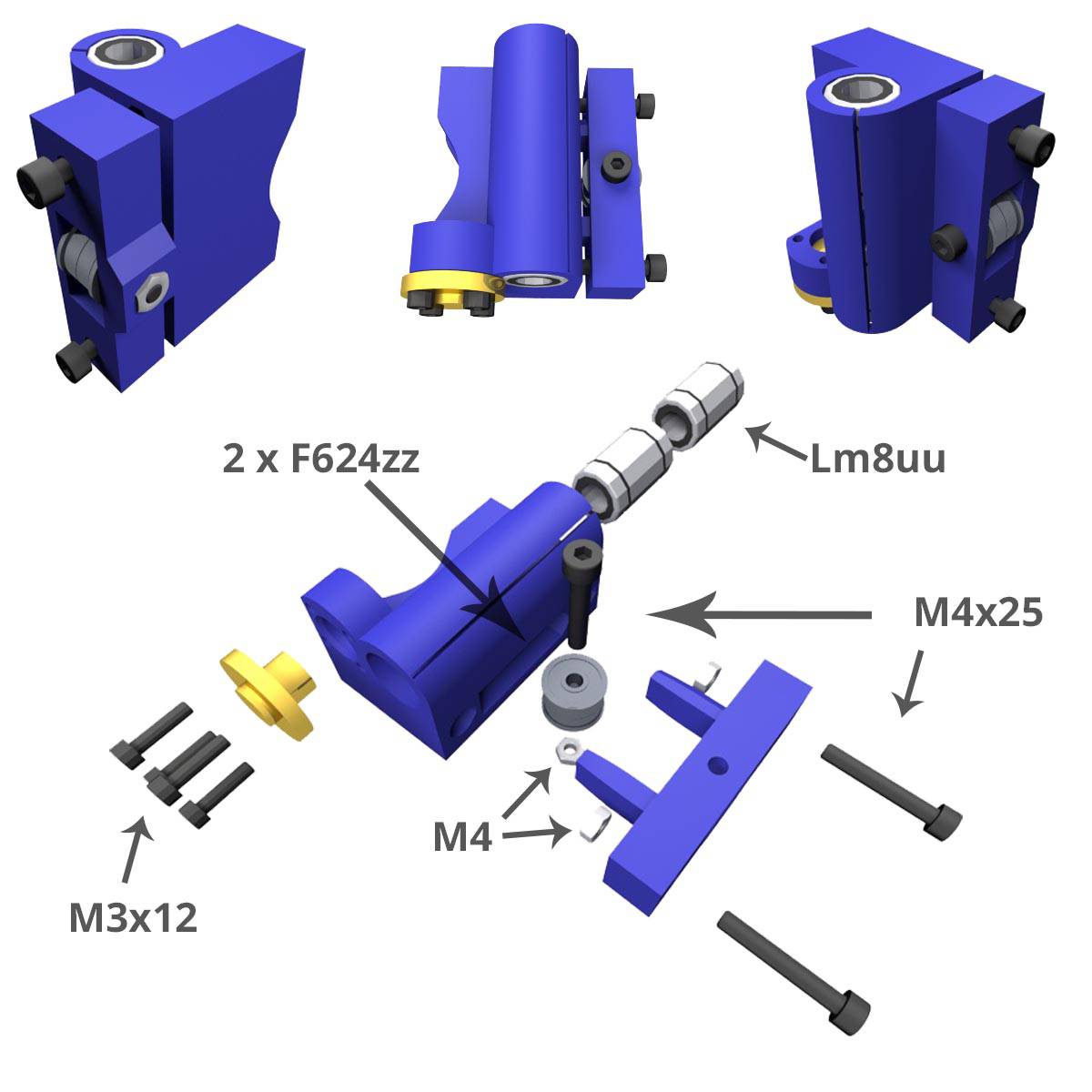

X idler, Leadscrews version:

Extruder detail, Leadscrews version:

HotEnd detail, Leadscrews version:

Connection Diagram of RAMPS 1.4:

Order and Orientation of the Stepper Motor wires:

Keep the colour order of the wire; the RED wire goes DOWNWARDS when connecting to the RAMPS.

Additional considerations:

- Connect limit switches as indicated in the video or scheme, an incorrect connection can damage the Mega board.