The most significant features of HPRO-330

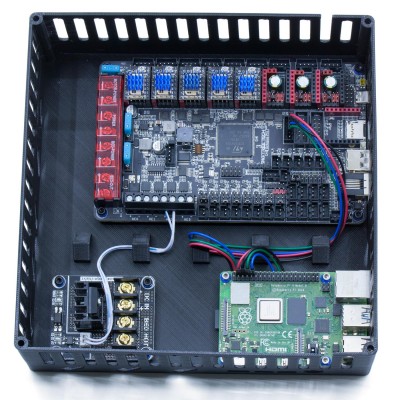

Klipper is the ideal firmware for high performance 3D printers.

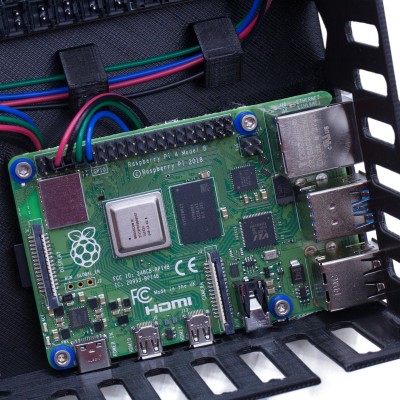

It uses a microcomputer (Raspberry Pi) to make all the necessary calculations, both those related to the movement of the machine, and the temperature settings.

By having a great computing power, the trajectory calculation is very accurate, and with a position update frequency many times higher than other firmwares such as Marlin.

This translates into:

Higher print quality and better finishes.

Higher printing speed. Less vibration and noise during printing.

All the advantages of having a microcomputer, such as Wi-Fi connection, option to connect peripherals such as video cameras, remote control, etc.

Each printer includes an original Raspberry Pi 4 board, installed and configured, with its micro SD memory card.

Equipped with a powerful quad-core ARM Cortex-A72 processor at 1.50GHz manufactured in 28nm and with 3 memory configurations, the new Raspberry Pi 4 is a great leap in the Raspberry Pi family, betting on power and versatility, while maintaining a very tight price.

The new Raspberry Pi 4 is the true replacement for a PC.

Main features:

Broadcom BCM2711 1,50GHz 64bits Quad-Core Cortex-A72 VideoCore VI 500MHz Graphics 4Kp60 HEVC decode Memory LPDDR4-3200 1GB WiFi 2,40GHz/5GHz b/g/n/ac Bluetooth 5.0 BLE Real Gigabit Ethernet 2x USB 3.0 + 2x USB 2.0 2x Micro HDMI with dual monitor support

We include already configured a very complete set of macros, which includes the intelligent levelling of the hot bed.

With this configuration, the printer will take a sample of dots in the area of the bed that we are going to use for printing. This has several advantages over probing the bed completely before each print:

-We save time, since if the part is small we will take fewer reference points, and also the displacements will be smaller.

-The number of dots is automatically adjusted according to the size of the part.

-The density of points will always be ideal, few points very close together for small parts. And many dots with the right spacing for large parts.

These parameters can be adjusted to always achieve the perfect first layer.

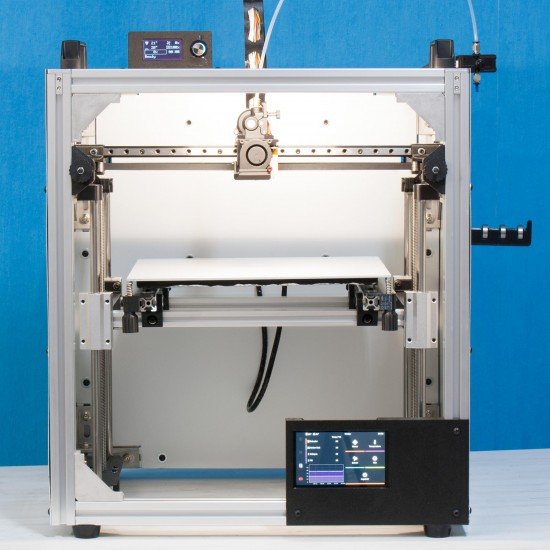

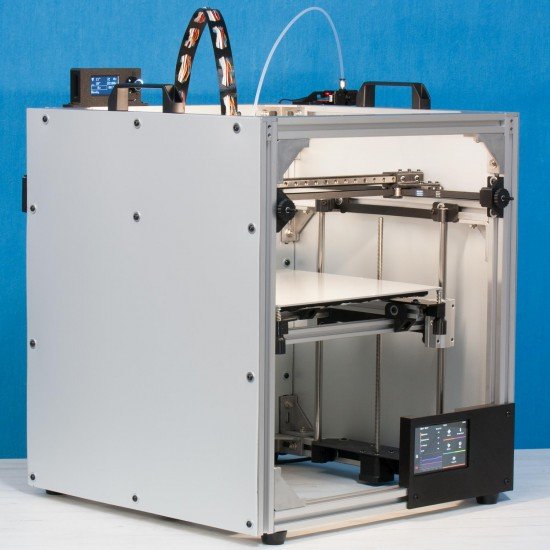

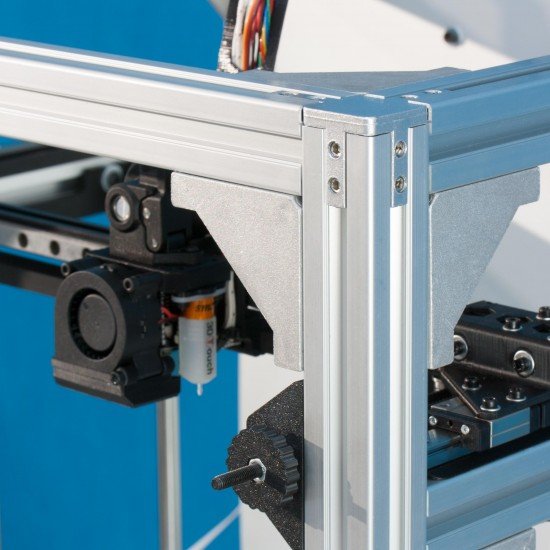

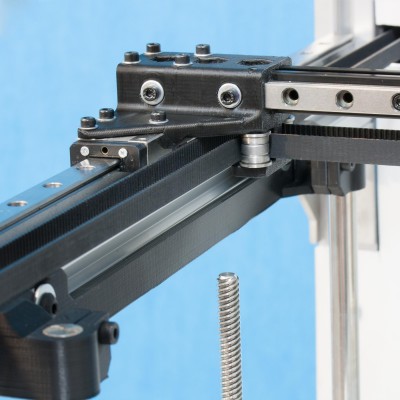

The 3030 profiles provide the HPRO with high rigidity and stability. It is one of the key components to deliver such performance. In addition, it is equipped with 3060 brackets, which will minimize the possible oscillations that occur during high-speed printing. This structure design also allows for easy customization of the printing volume. Their geometric shape makes them ideal for printing farms, since they have a large printing volume compared to their physical volume.

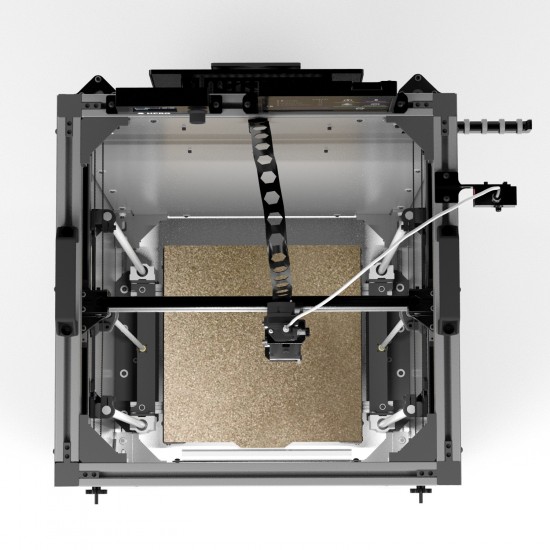

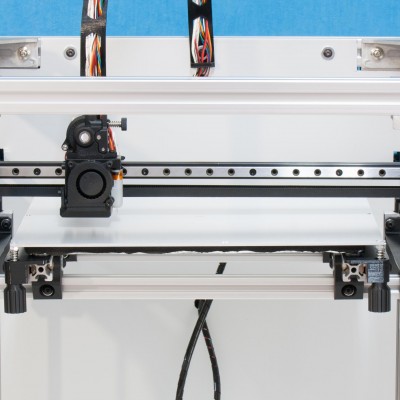

This motion has unique characteristics.

Compared to Cartesian printers, it offers higher speed and accuracy because neither of the X or Y motors move, as with the core XY system.

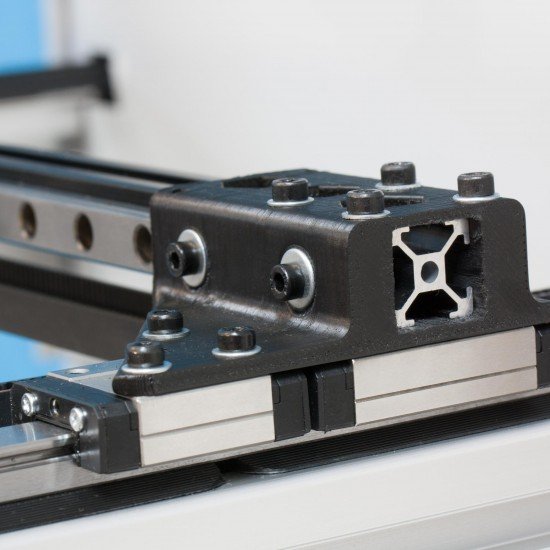

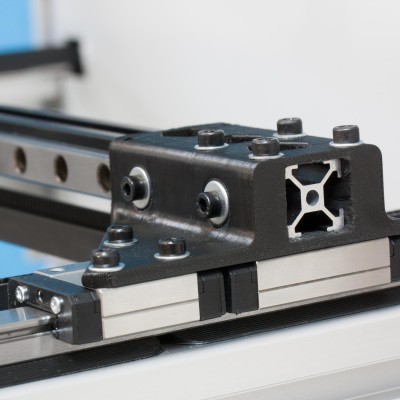

Compared to the core XY system it is very similar, since the movement of the X and Y axes is achieved by moving both motors at the same time. It requires more rigidity in all its elements, that is why we have 4 skids in the Y axis. This rigidity also translates into greater precision.

In exchange for adding these two carriages we obtain the following advantages:

-A single belt, with a single tension, so that we will not have problems arising from the difference between tensions, such as loss of perpendicularity.

-The belt path does not cross, it is all in the same plane, so there are no torsional forces on the belts.

-By using a single belt we save space and we can use a 9mm belt, which will last longer and can transmit more forces.

-There are only 6 pivot points where the belt makes a 90 degree angle. By reducing the number of bearings and moving parts, we reduce maintenance and the possibility of failure.

This motion is specially selected for 3D printing farms and professional users.

Linear guides are precision elements that offer a simpler, lighter and more precise assembly. These guides have less mechanical play than conventional linear bearings, suffer less wear and tear and are more resistant to the passage of time without backlash. They are the preferred solution for precision and high performance machines.

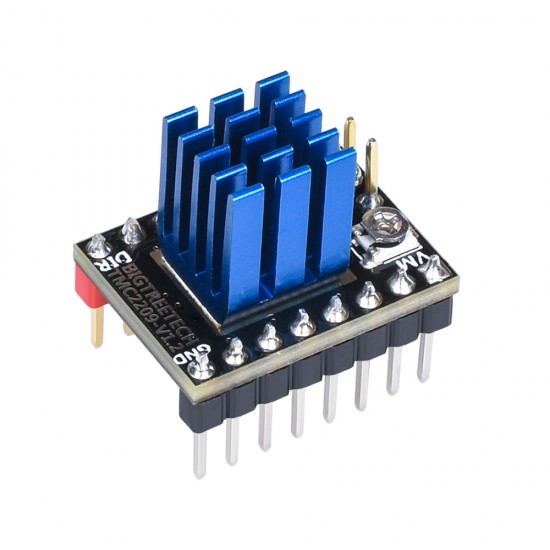

These 52 N-CM motors for X and Y are very strong and allow you to take full advantage of the silent mode of the TM2209.

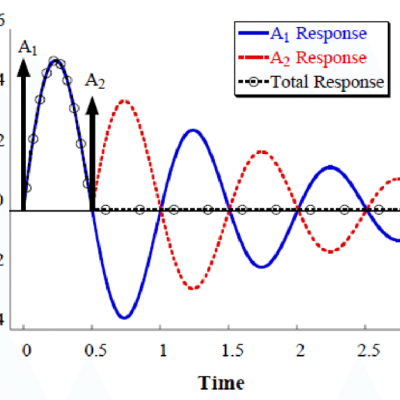

Resonance compensation is active and calibrated, so that we can increase the printing speed, minimizing its impact on the print finish.

In other words, we can print very fast without it being noticeable, or we can print at intermediate speeds with a surface finish equivalent to slow prints.

It also allows us to use higher accelerations without causing visible artifacts.

Each motor is controlled independently, so that when the macro is started it automatically checks that both are synchronized before each print. This avoids problems with heavy printing and calibration operations.

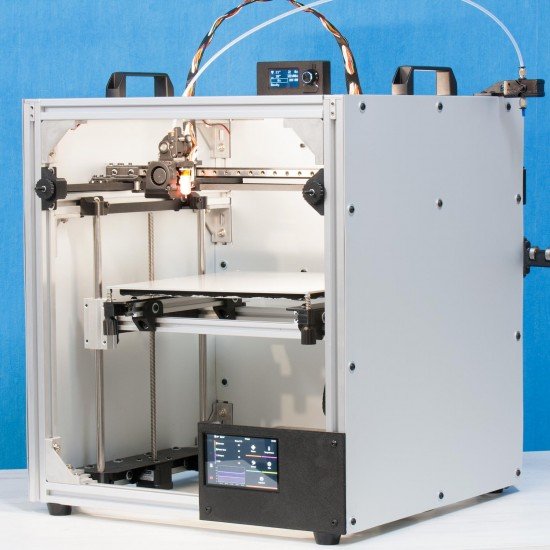

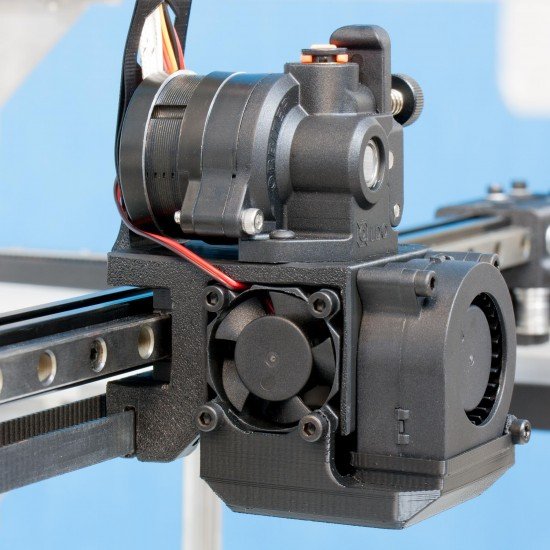

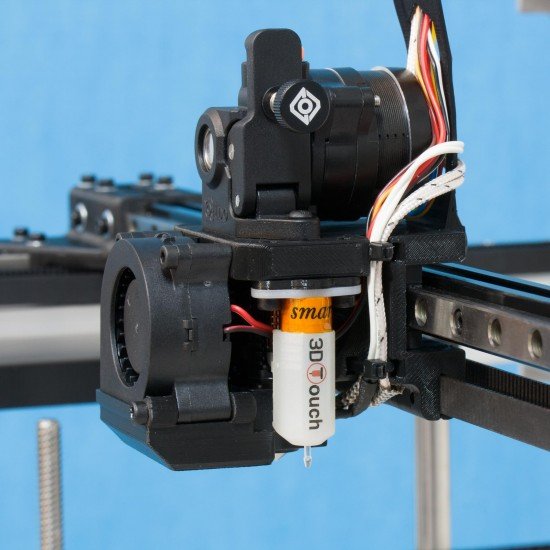

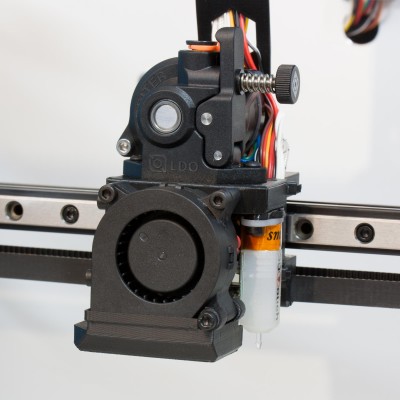

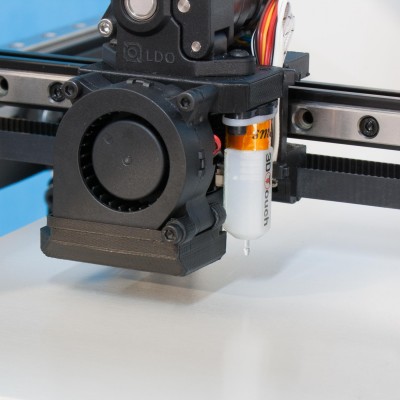

-Weight reduced to ~135 grams. -Stainless steel filament exit guide with 0.2-0.3mm clearance to drive gears for best TPU printing experience and extreme wear resistance when using abrasive filaments.

-High temperature resistant housings, GPA12.

-Extremely low backlash ~0.06mm.

The Phaetus Dragon hotend is a type of all metal bimetal hotend comparable to a hybrid between the E3D V6 hotend and the Mosquito hotend. It includes a bimetal throat with the same thermal principle as the Mosquito, achieving a thermal break far superior to other popular models such as the V6. The HF version offers a much higher flow rate than the normal version, it is equivalent to a Volcano hotend, but shorter. It can reach up to 30mm3/s. The combination of the Orbiter extruder with the Dragon hotend, achieve a very short filament path from the extruder pulley to the melt zone, this is very favourable for printing precision and compatibility with flexible filaments.

The color touch screen offers a simple, comfortable and complete interface to manage our printer, from it we can among other things: -Configure our wifi network. -Control the printing status. -Manage our collection of Gcode files. -Use advanced functions such as "Exclude Objects".

Thanks to the Hotend and its four-point clamping system, it will not rotate, allowing easy nozzle changes with just one hand. In addition, it is compatible with all V6 nozzles, including high-flow nozzles, offering a wide range of possibilities.

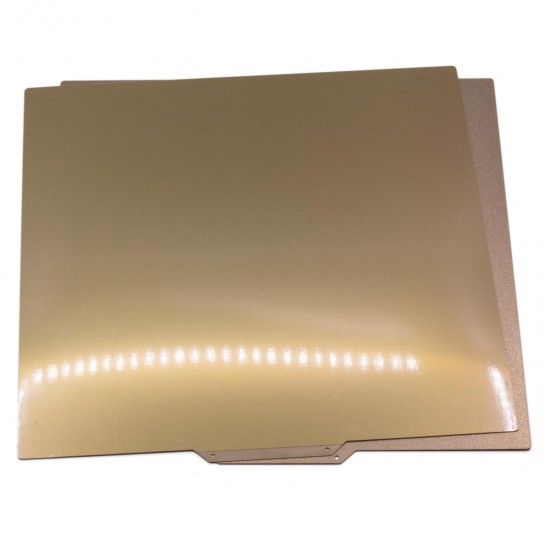

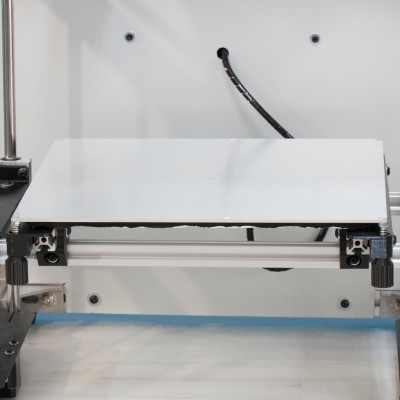

Large format printing base, that will provide enough space to print your biggest projects. With enough power to reach up to 110ºC, and print PLA, PETG, ASA, ABS, etc. It can be configured with borosilicate tempered glass (ideal for technical plastics) and/or with magnetic strap, for convenience and general use. It is insulated at the bottom for greater energy efficiency.

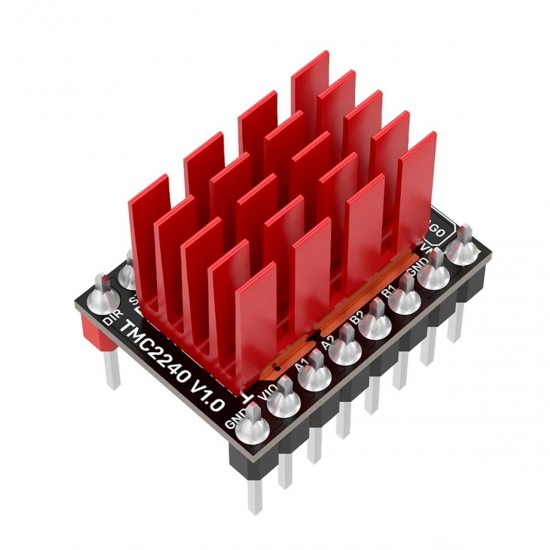

Its electronics are widely configurable, and upgradeable, so it is ready for countless improvements and additions that may appear in the coming years.

Both Raspberry and Klipper are open source programs, practically everything that is compatible with Klipper will also be compatible with your HPRO.

Modular structure and configuration. It is designed to be easily expandable and configurable, we will soon offer more configuration options, such as new extruders and even multi-material printing systems.

You can visit our repository at this link: https://github.com/hta3d/HPRO

Developed by HTA3D in Spain. All these years operating a 3D printing farm with thousands of customers, has given us a clear vision of what professionals need, beyond marketing and competition to offer the lowest price. Our vision is to offer a machine with top quality components, prioritizing performance and durability. Quality and technical service are our hallmarks, and we wanted to put all our know-how into this printer.