We all want our 3D printers to always print as good as the first day. We also want to avoid breakdowns and printing failures. For this it is very important to have a good maintenance plan.

3D printers are additive manufacturing machines, a type of CNC machine, and although they are becoming easier to use, we must not neglect their maintenance.

Below we recommend one as a reference. You can adapt it to your particular needs.

We will distinguish between 3 types of operations:

- Corrective.

- This is the first maintenance that existed until the First World War. It consists of fixing a fault once the failure has occurred. On simple machines it may be sufficient, but on more complex machinery such as our 3D printers it is inefficient. There is no reason to wait for a fan to fail before cleaning or changing it, if we change it before we save the consequences of that failure.

- Preventive.

- These are the operations that we carry out from time to time, just in case. It may not be necessary, but the cost of time and materials is more favourable, even if it is not necessary, than the possible damage that may be caused in the event that it is necessary and it is not done. A very clear example is the cleaning of fans. It is quick and cheap, but if it is not done in time, it can cause expensive breakdowns.

- Predictive.

- The most advanced of these three types of maintenance consists of changing an element when we have indications that it may soon fail. It is better than changing every X hours, as we avoid unnecessary expenditure of materials and time, and better than waiting for it to fail. If we continue with the examples of fans, when we observe that a fan is malfunctioning, it may be a good time to replace it. But if we see that it is working properly, even if it has many hours of use, we can maintain it for a longer period of time.

- A good maintenance operator, experienced in 3D printing, can identify a problem component before it fails.

| Equipment |

Description |

Type |

Frequency |

| Extruder | Cleaning of extruder pulleys | Preventive | Weekly |

| Extruder | Check bowden tubes and connectors, and replace if signs of fatigue are found | Predictive | Weekly |

| Extruder | Check wiring and connections, and replace/repair if any cables or connectors are damaged | Predictive | Weekly |

| Extruder | Check filament tension (should mark but not flatten the filament) | Preventive | Weekly or when changing to a more or less rigid material. |

| Extruder | Check the condition of the gears, and ensure that there is no excessive wear | Predictive | 1000 hours of printing |

| Hotend | Check that the material flow is correct | Predictive | 100 hours of printing or material change |

| Hotend | Check the condition of the heatsink, if it is dusty or dirty it must be cleaned for optimal dissipation | Predictive | 100 hours of printing |

| Hotend | Check the condition of the nozzle. If it is worn, it must be replaced | Predictive | 100/500 hours depending on the abrasiveness of the material used. |

| Hotend | Perform a flow calibration | Corrective | Whenever overextrusion or underextrusion is observed in the anterior impression |

| Hotend | Checking the wiring | Predictive | Weekly |

| Hotend | Check PID calibration | Corrective | Each time we observe temperature variations in the previous printout |

| Hotend | Calibrate PID | Preventive | Quarterly |

| Hotend | Fan cleaning | Preventive | Monthly |

| Hotend | Change fans | Predictive | When they vibrate excessively, make noise, or lose airflow. |

| Hotend | Change fans | Preventive | 50,000 print or as indicated on your model. |

| Base | Remove remnants of the previous print | Preventive | Each print |

| Base | Clean with mild soap and water | Preventive | Where there are visible traces of lacquer or adhesive residues |

| Base | Replace print bed | Corrective | When it has visible marks and scratches |

| Base | Check that the Z offset setting is correct and adjust if necessary. | Preventive | Each print |

| Axis | Clean rods, spindles and guides with absorbent paper and lubricate again. | Preventive | Weekly |

| Axis | Check screws, motors, pulleys, trolleys, if any have loosened, retighten them. | Preventive | Weekly |

| Axis | Check belt tension | Preventive | Weekly |

| Axis | Check wiring and terminals | Preventive | Monthly |

| Machine | Cleaning of material residues, threads, etc. | Preventive | Each print |

| Machine | General visual check | Preventive | Each print |

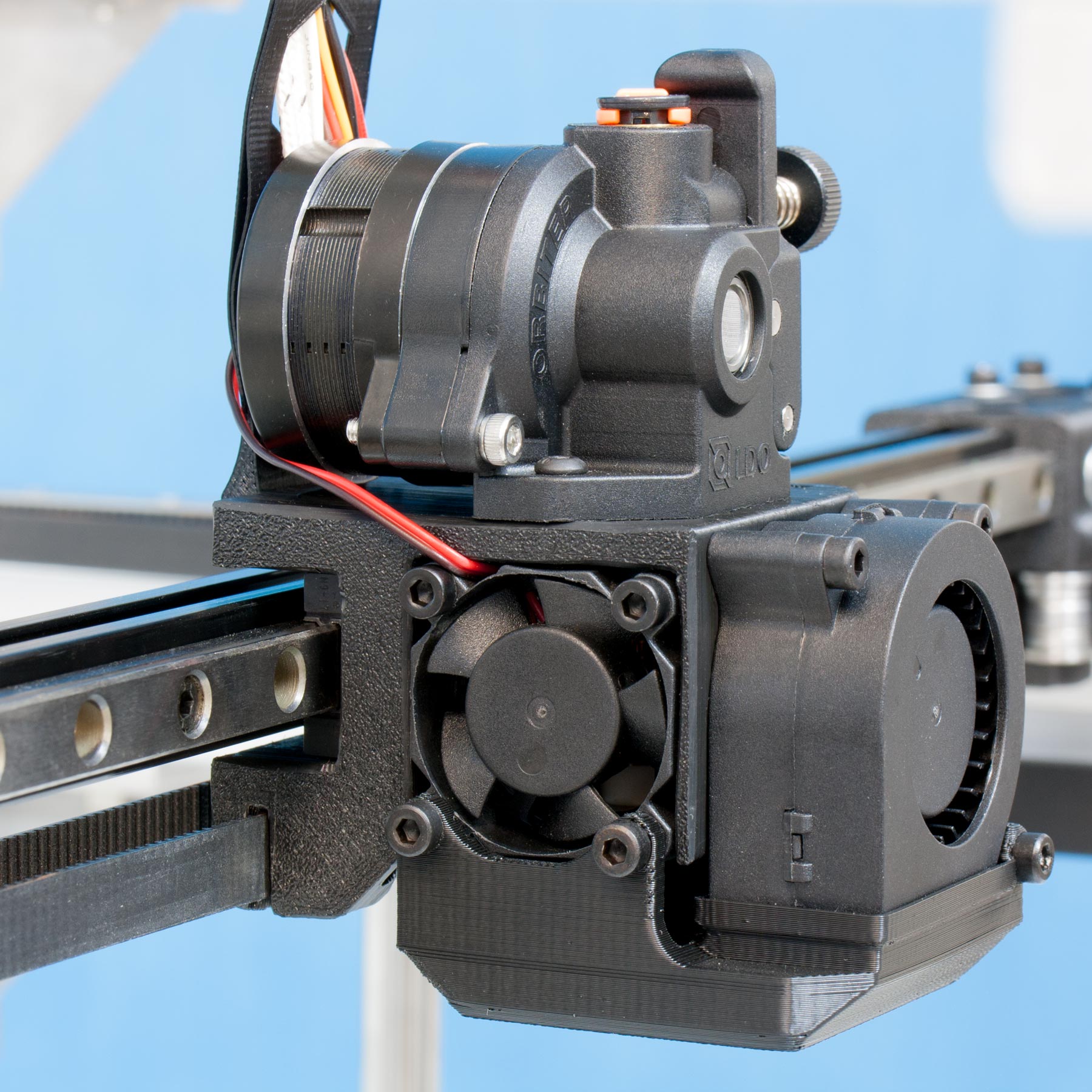

Extruder

It is the part that pushes the material, it is very durable and resistant, but a failure in this part can cause a jam, and spoil the printing. It could also damage the fuser.

However, if we always keep it in a perfect state of maintenance, this will help us to get more accurate and beautiful prints.

The quality of the components is very important in this component. Cheap pulleys wear more easily, as they are made of soft materials. Hardened pulleys will save time and maintenance costs.

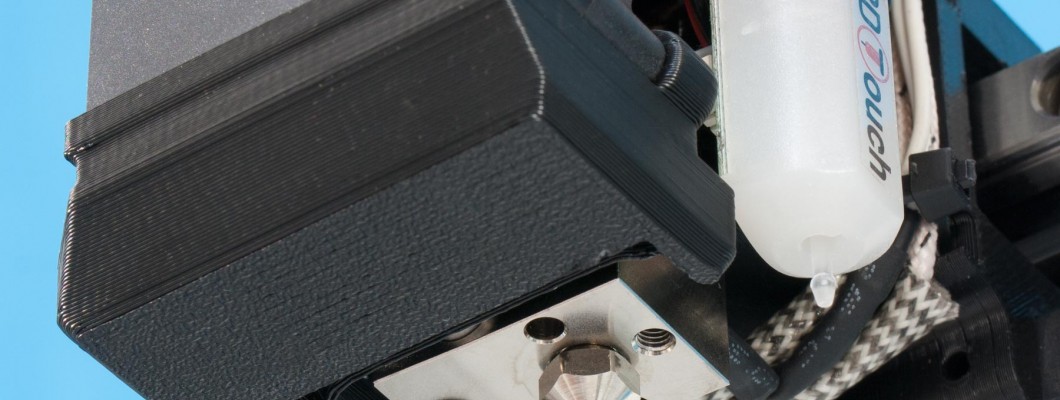

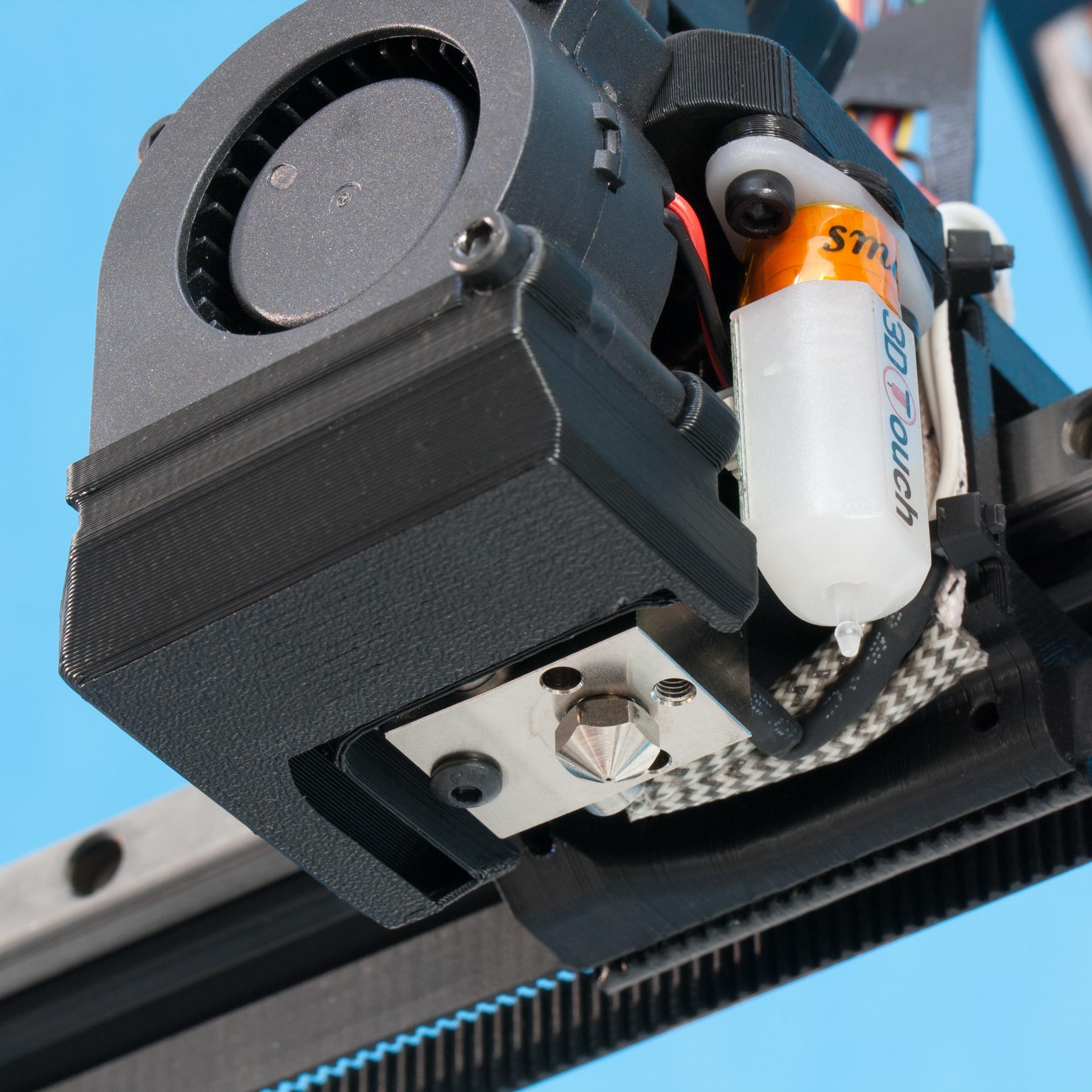

Hotend

If we keep the material in good condition, we will achieve a more stable and precise material flow, which will have an impact on the quality of the parts, their dimensions and finishes. In addition, we will avoid jams, some of which can be very cumbersome to solve.

Materials with impurities or abrasives can cause premature wear, this must be taken into account when choosing our melter and the materials we are going to use.

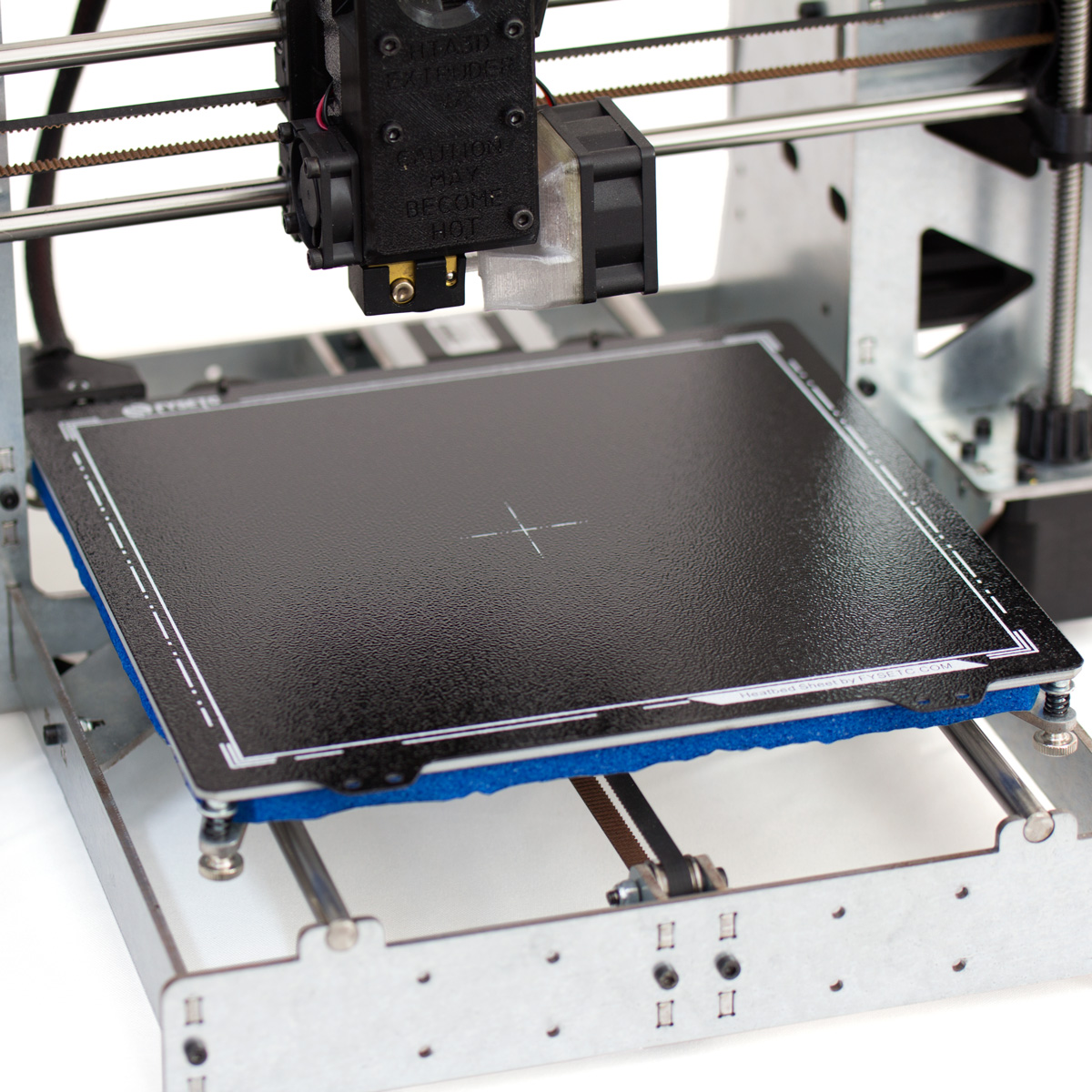

Base

If we keep it in good condition, the first layers will look better. In addition, we will avoid possible material peeling off, which could cause damage to the machine.

Some bases such as glass are more durable but require additional adhesives, other bases such as PEI are more delicate, but require little or no additional adhesives.

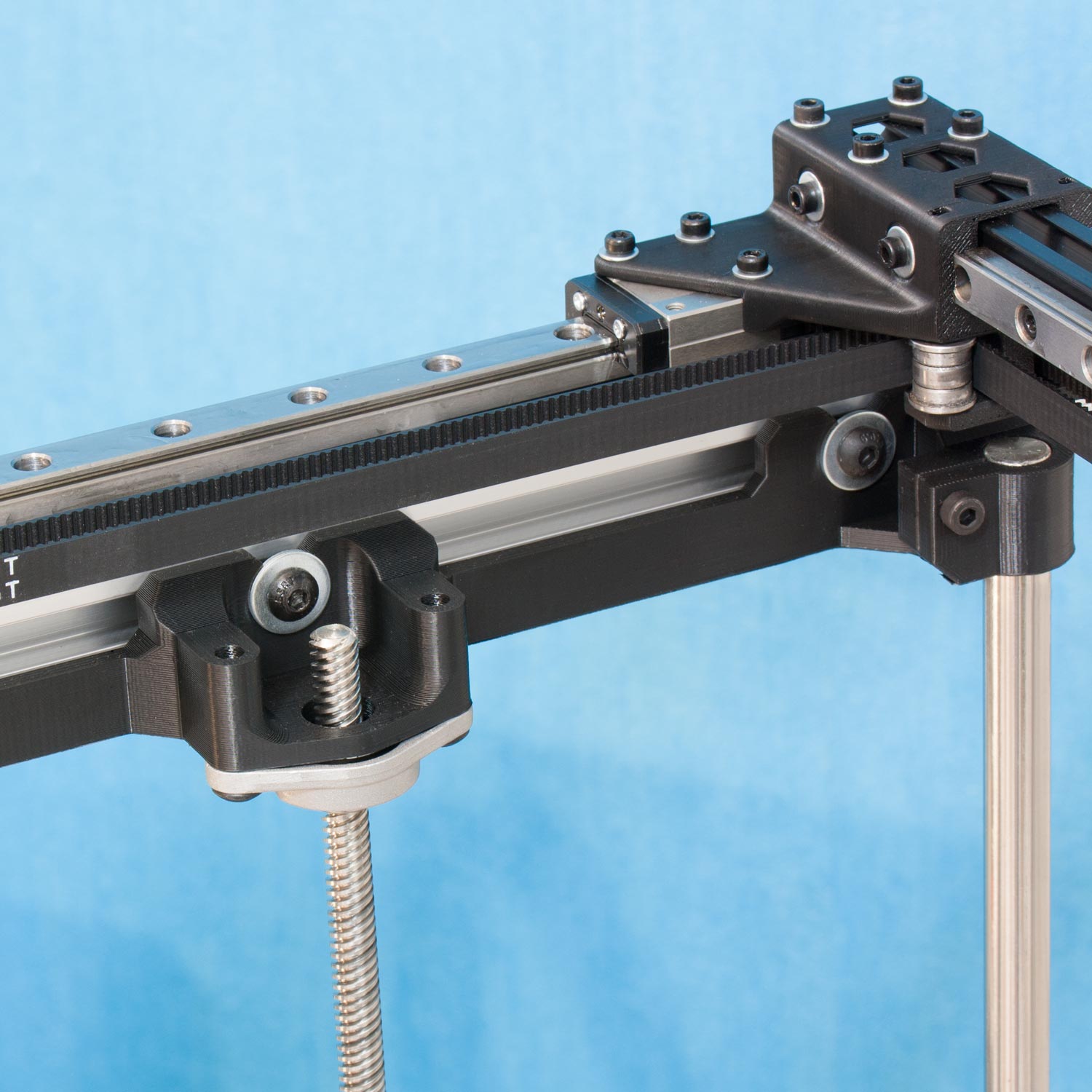

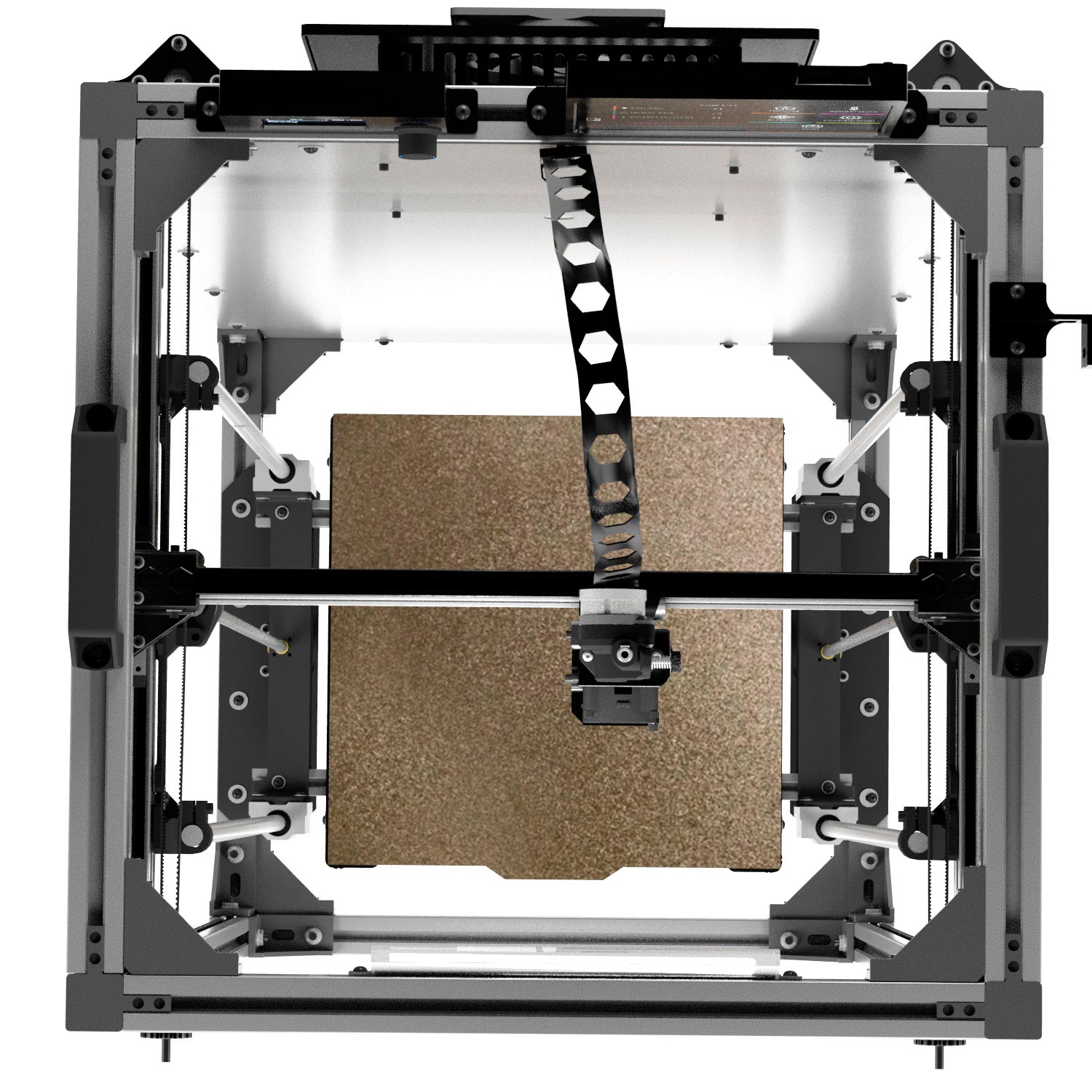

Axis

They are in charge of the movement of our machine, as long as they are smooth and free of play, they will produce better, smoother, quieter and more precise movements. And this in turn will be reflected in the finish of our prints.

Shafts in poor condition can lead to loss of pitches and serious faults.

Linear guides have a very long service life, and take up very little slack during use. V-Slot pulleys, on the other hand, are the opposite case, they suffer a lot of wear and tear and have a very short service life. In professional environments it is advisable to avoid components with a short service life.

Machine

In addition to each component, we can see the machine as a whole, it is always advisable to observe it carefully, frequently, a coil that is about to come out of the support, a rest of material that is close to falling on the belt, are elements that we can easily see and solve them before they cause a breakdown. .

Our advice is that every minute we spend on preventive/predictive maintenance of our printers is a minute or more we save on repairs. Moreover, maintenance is easy and inexpensive, while repairs are complex and costly..

Leave a Comment