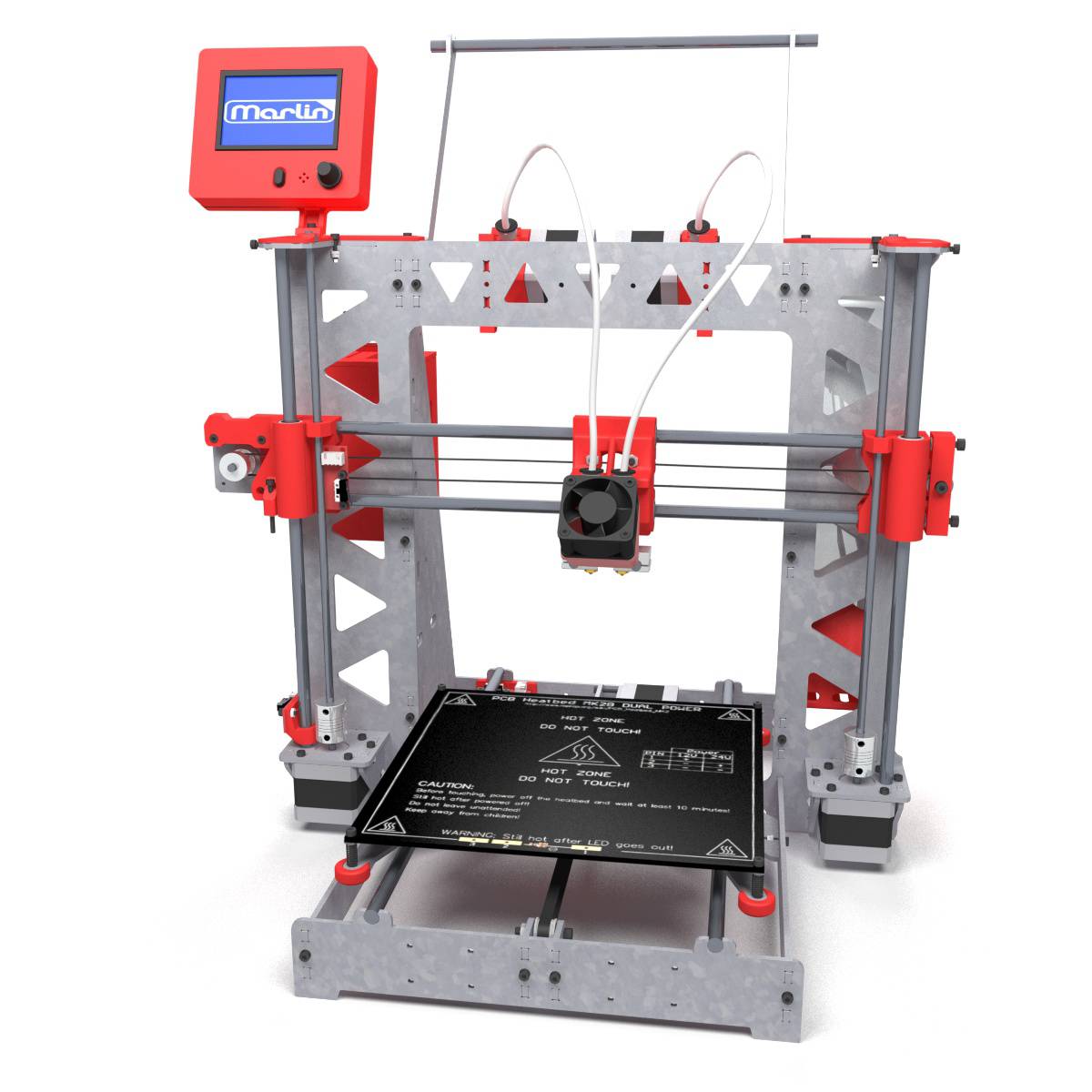

Many of you have asked us for a Dual P3steel kit, and today is the day: we have designed this kit for you. It is based on our popular P3steel, we have taken care of every detail in order to offer an easy assembled kit and easey to use, as well as very realiable.

Among its features we point out:

It is assembled with the same frame we use for our single extruder P3steel, so for all of you who like to modify 3D printers and make tests, you can find here an interesting project.

We have designed the extruder from scratch, placing it in a very discreet and accessible position, that minimizes the path of the teflon tube. Also, there is a very small distance from the stainless steel Mk8 pulley and the printed part, which is ideal for having the possibility of working with the bigger amount of possible materials.

The hotend has a fast leveling system for the nozzles heights, accessible from the front of the printer. Thus, the height nozzle calibration won't be as tedious as it is in other models.

It has a firmware controlled layer fan. How is this possible? We have added a Mosfet Module that controls this fan, so we don't have to give up anything!

Very complete video tutorial, in this occasion we have gone beyond the assembly, explaining two very important points: material flow calibration and a very accurate offset nozzles calibration.

Who is this kit recommended for?

For its price and the detailled instructions, it is recommended for everyone who is interested, but especialy for those who have experience in 3D printing. If it is your first 3D printer we recommend you to start with a single extruder, and once controlled it, start also with the dual extrusion, as it adds possibilities but also complexity.

Which are the advantages of dual printing?

It opens up a wider range of possibilities as, for example, using different properties materials, parts with flexible zones and rigid zones, circuit printing thanks to the conductive filament, combining two colours, using soluble supports, etc.

What difficulties can we find?

The head which isn't active, depending on the material, it is prone to free some drops by gravity. Nowadays, the best tools to deal with this are in Simplify3D programme, which isn't free, although it is planned to be incorporated very soon also to costless programmes as Cura.

If you have any question, please, don't hesitate in asking!

3 Comment(s)

Yo tengo una maquina nueva y no funciona estoy desesperado

que le pasa ??

Por favor envíe información detallada del problema a nuestro equipo usando este email: soporte@hta3d.com \r\nNo olvide incluir el número de pedido y si es necesario alguna foto para que podamos ver con claridad el problema.

me gustaría obtener de nuevo (lo he perdido) el marlin 2 para mi p3 steel dual.\r\n\r\nUn saludo

Los enlaces están públicos en la pestaña "descargas" de la descripción del kit. Tanto las versiones antiguas como las mas recientes. Saludos!

Hola, tengo una P3Steel de hace unos años que ahora mismo no funciona ya que se me ha estropeado la placa y la fuente de alimentación. No la he arreglado ya que tengo además una 3DSteel v2 que es la que uso actualmente.

Había pensado aprovechar la P3Steel para instalarle el extrusor dual. ¿Hay algún tutorial de cómo pasar de una 3DSteel a una P3Steel Dual donde se especifique qué componentes harían falta?

Gracias

Te aconsejo actualizar la P3Steel a 3DSteel V1 o V2, según nuestros tutoriales del blog. No tenemos tutorial para pasar a dual.

Leave a Comment