3DSteel V2, the ideal 3D printer for educational centers

3D printing is becoming increasingly important in our world. From individuals who can manufacture custom objects to new forms of manufacturing for companies, which makes production more flexible. Therefore, the knowledge of its operation and use will be a very useful tool in the future of children and adults in training.

Why is it a good decision to give a 3D Printing course?

A 3D printer is a machine with a relatively simple operation, but that involves learning from various technical aspects:

- Mechanical and structural.

- Electrical

- Electronic.

- Programming.

- 3D modeling and preparation of code for printing.

Depending on the focus you want to give to the course, you can place more or less emphasis on each part. 3D printing is a multidisciplinary technology, so training on it is open to many different options.

At a basic level, you can assemble the printer, naming its parts and operation, and print a few simple parts.

If you want to go in depth, you can talk about electronic components: what function each component performs, its advantages over others, technical specifications, etc.

At the programming level, you can go into seeing the firmware of the printer that, although you do not need to make modifications, they can become familiar with the computer language, in this case Arduino.

The course can be complemented with 3D modeling classes and preparation of the codes for the printer.

What can it bring to the students?

- Teamwork: They will have to cooperate in assembling the machine, dividing parts or coordinating tasks.

- Acceptance of diversity: Possibly students start from scratch or a basic base, and will be in a position of equality which helps the acceptance of diversity.

- Motivation: Working on building something that they can later use increases their interest in the project.

- Troubleshooting: They will have to face possible doubts that arise in the assembly and solve them.

- Thinking in 3D: They have to learn to design in 3D, which invites them to think differently, solving mental puzzles on how to create the piece to make it printable.

3DSteel V2

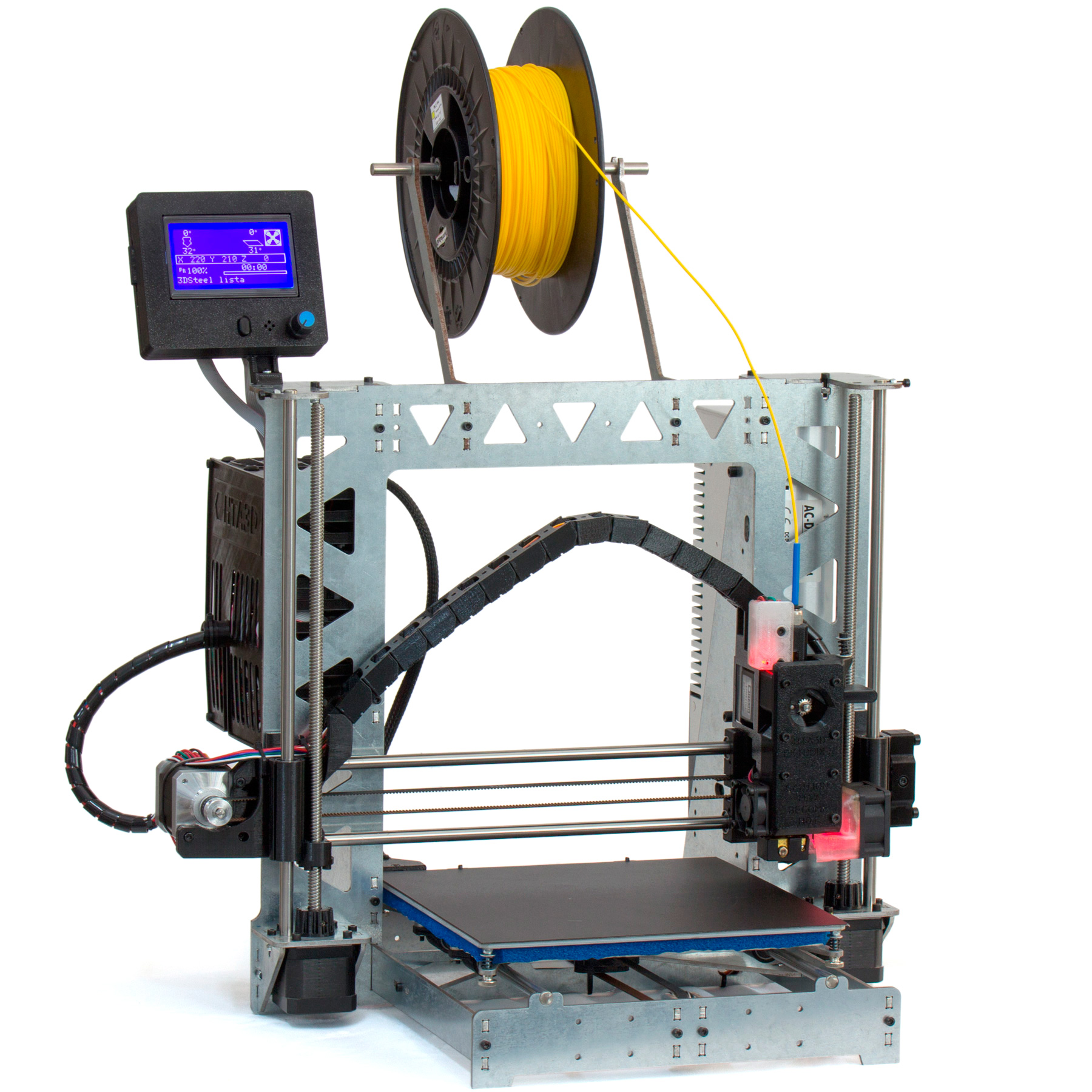

Our 3DSteel V2 printer is a printer that includes the most innovative and demanded components on the market. With it, we have achieved a versatile and efficient printer. Some of its features to highlight:

- Steel structure: the best possible structure for a 3D printer, the design of this frame makes assembly as simple as fitting a puzzle.

- 32-Bit SKR V 1.4 Board - 32-bit processor with plenty of power to use all available Marlin features without memory or processing load limitations. In addition, this very reliable board includes a high-power mosfet that will not overheat.

- TMC2209 UART Controllers: Chips designed and manufactured in Germany. It guarantees a smooth, silent and precise movement, in addition to being controlled by Marlin through the LCD.

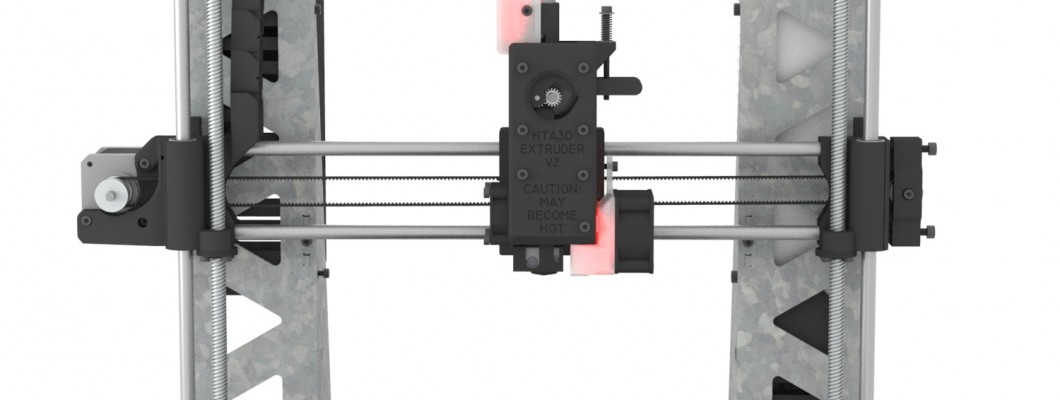

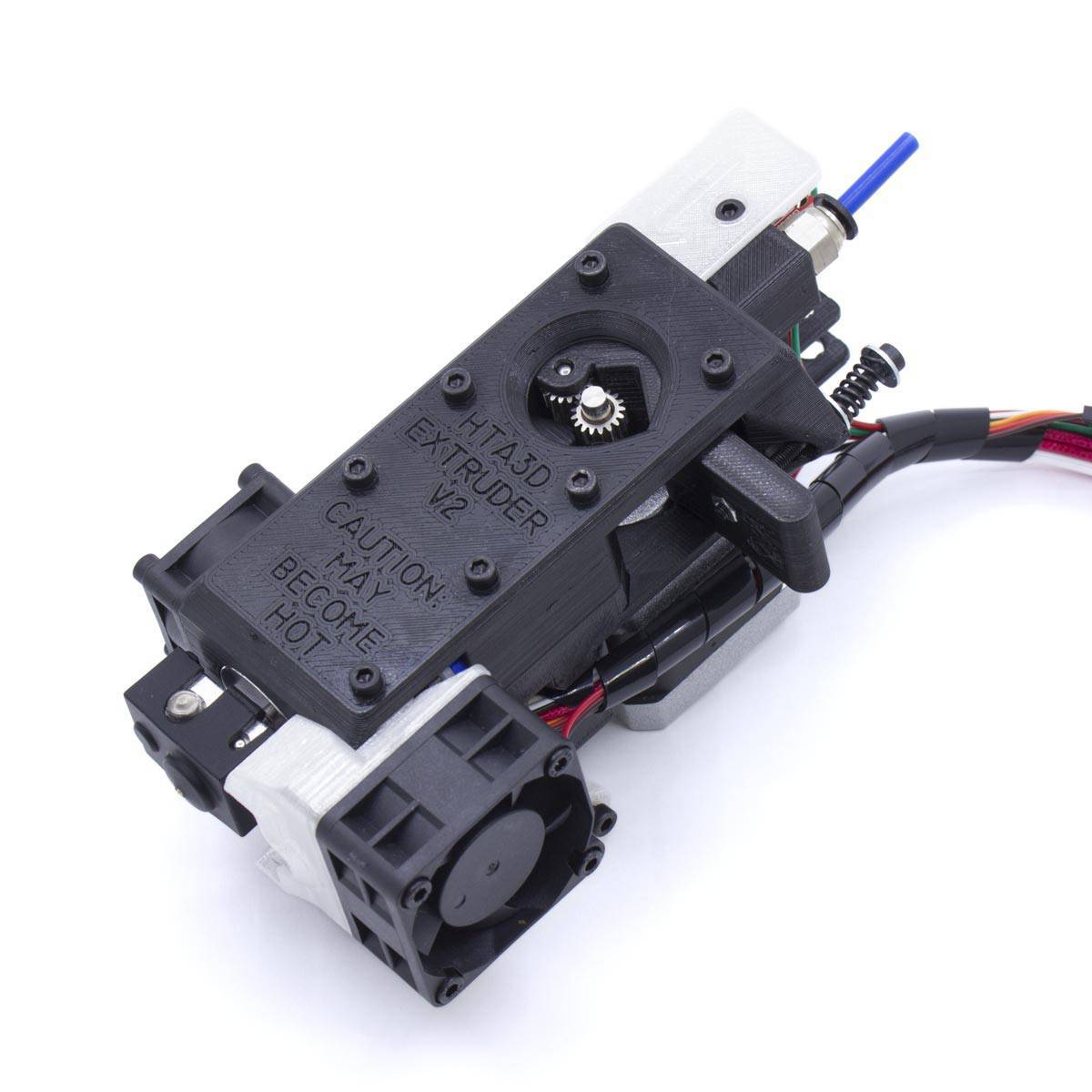

- HTA3D V2 Extruder: All-in-1 extruder that will delight the most demanding users. It includes everything you need in a very compact size: fuser, layer fan, extruder with dual pulleys, adjustable tensioner and filament presence sensor.

- 3DTouch Leveling Sensor: light and precise, it mechanically samples the position of the bed, correcting deviations or inclinations.

- Filament Presence Sensor: simple and reliable operation, it detects when the filament has run out so you can change it comfortably.

- 24V Power Supply With Smart Fan: a 24V power supply gives us better performance than the classic 12V ones, all components will work with better performance and higher power.

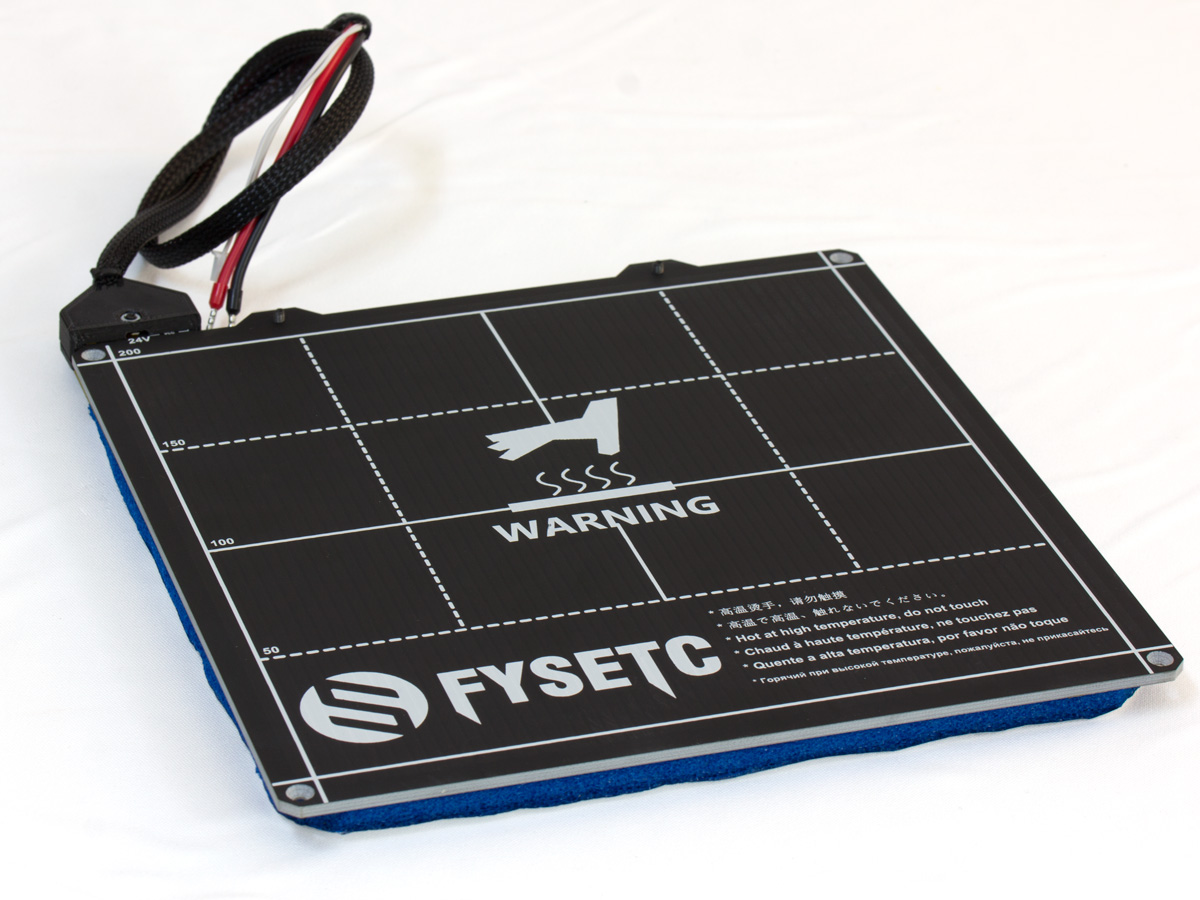

- 220x220mm Magnetic Heated Bed: very powerful, capable of reaching 120ºC of temperature quickly.

- Quality components: GT2 belts reinforced with fiberglass and with anti-wear coating, the assembly is designed so that they can be changed easily without disassembling almost anything, this printer is designed to last and have minimal maintenance costs.

Assembly

The 3DSteel V2 printer has step-by-step assembly tutorials, explaining in detail every point from the first screw to the first printing of the machine.

In addition, to facilitate and expedite it, a large part of its components are already prepared so that its assembly is reduced to assembling the structure and coupling the different components:

- The extruder is fully assembled.

- Calibrated and assembled power supply.

- Electronics with firmware loaded and mounted in its protective case.

- Wired heated bed, with insulation and welding protection.

- The X-axis components are ready to be assembled into the frame.

- LCD ready.

In this way, assembly is facilitated, making it suitable for all educational levels, and assembly times are reduced, being able to reduce the course time or use it in other explanations.

3DSteel V2 Assembled

We also offer the option to buy the 3D printer already assembled and calibrated, for cases in which you want to focus more on the use of the printer.

In this way, you will receive our 3DSteel V2 assembled and ready to print. We will send the test prints with it once it has passed our quality control.

We include a 300 gram spool of filament so you do not need anything else before you receive it.

Applications

With 3D printing, there are many sectors that are benefiting from the capacity it presents in the flexibility of designs and reduction of costs of prototypes and final products. For this reason, there are numerous uses that are given to 3D printers today, and that continue to increase, to name a few of them:

- Mechanical parts.

- Prototyping and mockups.

- Prosthesis.

- Jewelry and even textile design.

- Art.

- Household objects.

Our service

Our commitment to our clients does not end with the delivery of the products, but rather we support all the doubts that may arise during the assembly and use of the 3D printer. When buying the 3DSteel V2 printer, you make sure that you can contact its manufacturers, who will be available to answer any questions, which gives support and technical support to the educational center.

If you have any doubt, please, contact us through: info@hta3d.com.

Leave a Comment